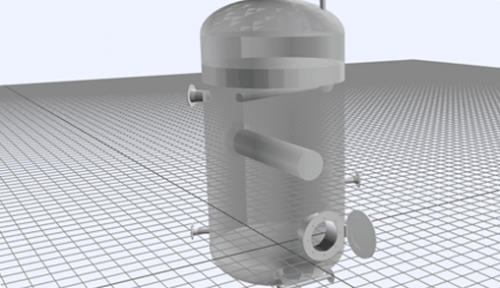

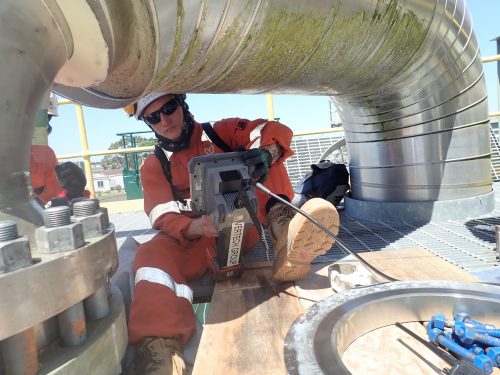

Vertech applies Advanced-RDVI as an integrated solution focusing on pre-planning and specialist execution packages to deliver high levels of data & results that can not only be used for pressure equipment sign-off but also for post-inspection analysis, risk reviews and process operational requirements.

The Vertech Advanced-RDVI team has over 60 years of RDVI experience, gathered from various industries, including Oil, Gas, Petrochemical, Pharmaceutical, Dairy, and Power Generation, worldwide. This ensures our clients have the right people, systems, equipment and support to meet all their remote inspection needs.