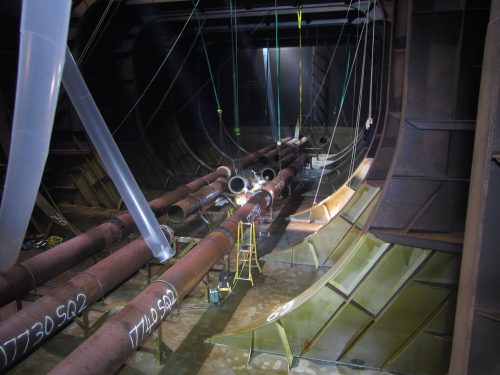

Vertech’s Marine and Class Inspection Department prides itself on its industry-leading services and proactive, solutions-based approach. The marine team is a highly experienced, dedicated team of office and site-based professionals who live and breathe hull structures and class rules. Our team specialises in statutory inspections for the classification of ships, such as tank surveys, crop and renewal surveys, UWILDS, special surveys, and other applicable class inspections for offshore floating structures and subsea infrastructure.

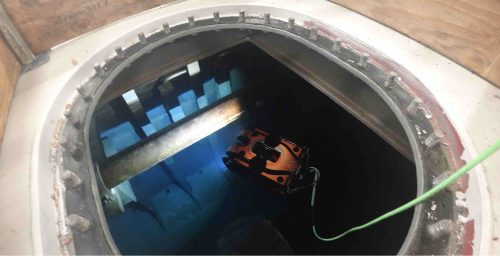

We use the latest technology, proprietary inspection tools, and cutting-edge software solutions to not only complete the inspection efficiently but also provide high-quality, repeatable, and compliant reports, models, and data sets that make it easy for the accrediting surveyor and client to achieve all of their specific project requirements.