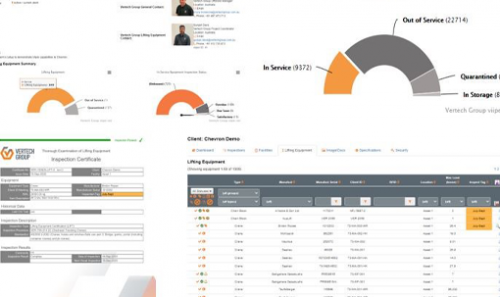

The V-LIFT Package is a collection of specialist services, systems, and products refined over a decade to provide unparalleled support for cranes and lifting equipment. The V-LIFT Package was first built with efficiency, quality, and compliance with Australian legislation in mind, then refined to maximise cost, time, and safety benefits for our customers. The package has been utilised by major downstream LNG operators, coal seam gas operators, offshore production operators and numerous upstream drilling assets over multi-year terms.