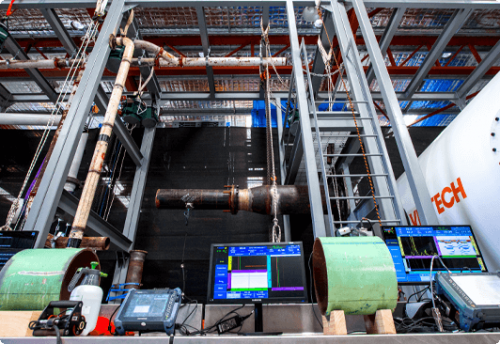

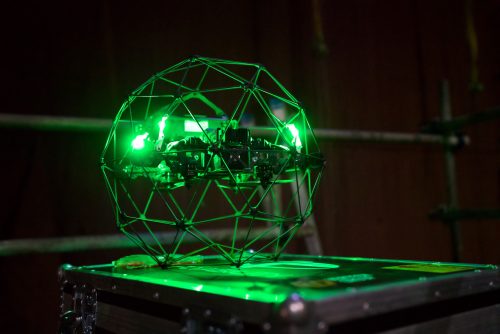

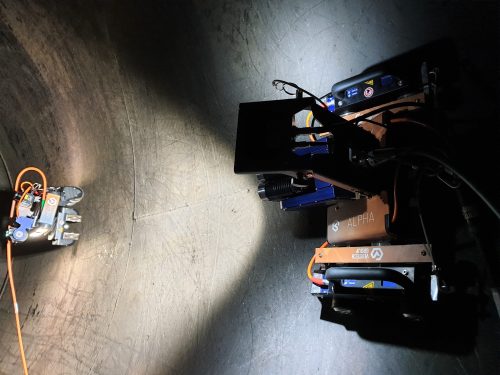

Vertech’s V-TAR Specialist Package provides comprehensive integrity, inspection, and access services tailored to specialist shutdown (SD) or turnaround (TAR) projects.

In the oil and gas, power generation, and mining industries, turnarounds (TARs) are critical to a facility’s ongoing operation. These peak and intense activity periods make it imperative to have the correct planning, the right equipment, and, most importantly, the best people.

A well-planned shutdown can positively impact the plant, have it running at capacity, and significantly extend the facility’s operating life.