Vertech was requested to conduct an RDVI review of the Barossa and Scarborough Facilities while still developing and designing. To do this, each item of pressure equipment was examined, from the process flow to the internal configuration of internal fitments, resulting in recommendations for dedicated RDVI nozzles being made.

Barossa & Scarborough Feed Reviews

This project’s scope was accomplished collaboratively through Vertech working closely with the NII team of sister-company Sonomatic. In doing so, Vertech has been able to compile a complete service package for Greenfield facilities to assist in engineering and designing requirements for inspection without a confined space entry scope.

Non-Intrusive Inspection

Non-intrusive inspection is a comprehensive external inspection strategy that eliminates the need for vessel entry during any phase of the engineering and exterior advanced inspection techniques.

Our group company, Sonomatic, was the vital author of the Non-Intrusive Inspection (NII) recommended practice HOIS-RP-103, pioneering the formal industry approach for NII.

Our team is the clear leader in implementing NII, having conducted NII assessments and advanced NDT inspections for over 2500 pressure vessels for significant operators globally. NII For pressure vessels is rapidly becoming the primary approach to achieving pressure vessel compliance and integrity review, replacing Internal Visual Inspection (IVI), which sees us aiming to eliminate confined space and crewed vessel entry by 2026.

Remote Digital Visual Inspection (RDVI)

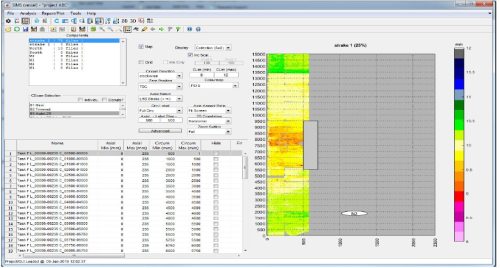

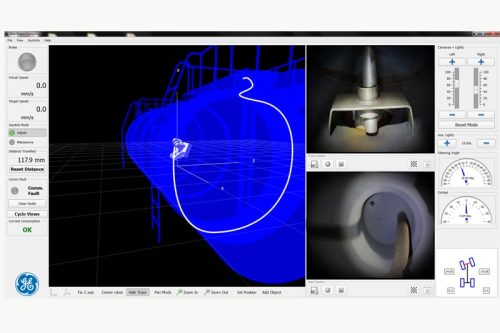

Remote Digital Visual Inspection or RDVI is the application of remote digital systems such as cameras, robots, or crawlers to internally inspect and assess challenging access areas without requiring intrusive inspections and the associated Confined Space Entry. RDVI methodologies work for condition assessment, process efficiency assessments and Foreign Object Search and Retrieval (FOSAR).

As a market leader in the application and planning of RDVI services, Vertech has a suite of norms across offshore platforms, FPSOs, LNG assets and refineries incorporating the knowledge of damage mechanisms applicable, access requirements and the suitability of different systems. Our RDVI front-end engineering and design (FEED) package was refined out of decades of deployments, experience and issues encountered.

Our Front-End Engineering Design Services Include:

- Project and program management

- Project Inspection Engineering

- Review of Pressure vessel design criteria

- Review vessel matrix and damage mechanisms

- Complete Risk review & prioritisations

- Advice on dedicated inspection access points

- Updated Pressure vessel nozzle configurations

- Update tertiary steelwork designs for NII

- Integrated planning with NII

- Guidance on online remote NDT Applications

SPEAK TO VERTECH GROUP ABOUT YOUR NEXT PROJECT

"*" indicates required fields