Vertech were engaged in mobilising a multi-disciplined inspection and specialist maintenance team with equipment to perform critical hull integrity inspections and heavy rigging to replace the cargo piping system within the hull of an FPSO. The team were able to reduce time and cost and get the facility back to full production ahead of schedule and under budget.

Marine Piping, Fabric & Maintenance

Vertech was contacted days before Christmas Eve to supply a multi-disciplined team. We assembled and successfully mobilised several highly specialised teams before the New Year to carry out an as-found assessment and NDT inspection of damaged pipework.

The Challenge

This scope had multiple challenges due to the confined space environment and technical scope requirements.

Our teams had to deal with high temperatures and limited space with multiple work groups and activities. Our team’s tenacity, professionalism, and ability to think outside the box were integral to the success of this scope.

The Solution

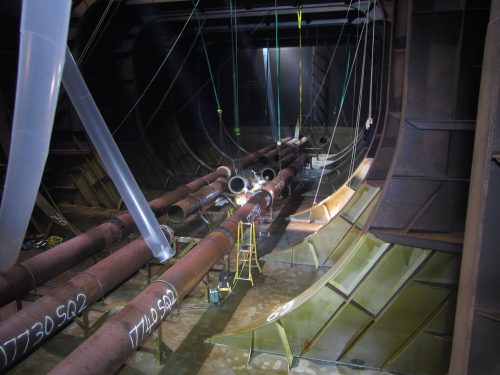

Cargo tank spaces have limited rigging points due to their design. Vertech’s rope access capability was integral in the success of this scope by providing rigging support for shifting damaged and repaired pipework as required, using the internal bulkhead and transverse web structure as primary rigging points for the successful execution of all rigging activities.

Vertech developed and executed comprehensive lift plans to ensure each lift was carried out safely and efficiently. Then, Vertech provided a 10-man multi-discipline team to support the ongoing engineering and repair execution.

Vertech’s multi-discipline specialist team was integral in the success of this scope with the supply of access solutions, specialist technical rigging, welding inspection, 3D modelling, ongoing NDT testing, and general ad-hoc repair support.