History of Koolan Island

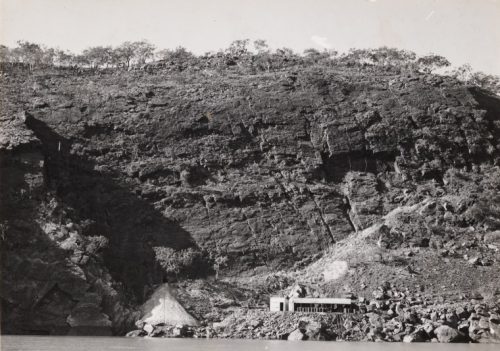

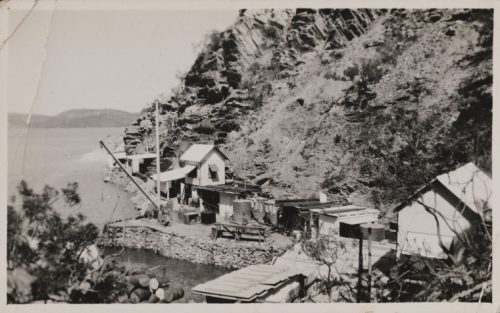

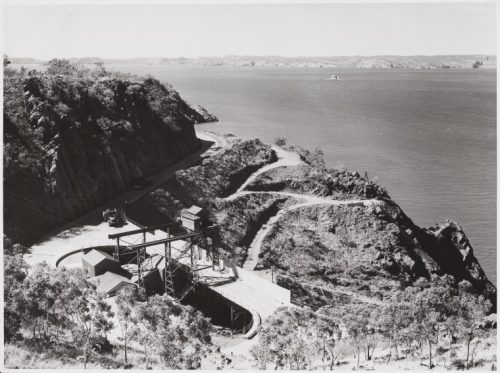

Images Sourced from the collections of the State Library of Western Australia and reproduced with the permission of the Library Board of Western Australia.

Images Sourced from the collections of the State Library of Western Australia and reproduced with the permission of the Library Board of Western Australia.

The meshing campaign is critical in stabilising rock faces. The mesh prevents rock falls and provides a surface for anchor points for ropes and harnesses.

Through working on previous meshing works, our engineers and technicians identified that using helicopters in meshing scopes was the most efficient way to get multiple rolls on walls quickly compared to using cranes. However, using helicopters requires a lot of preparation and planning before they can be deployed by site personnel. The practice of helicopter meshing is a complex process that involves much effort, time and resources. The first step is to plan the flight path and determine where the pilot will place each roll on the face. This needs to be done by an experienced pilot, who must communicate with the ground crew during flight operations.

Another aspect of using helicopters is that our technicians can use them in places that would be too dangerous for a crane. The aircraft can fly low over the ground and place the mesh rolls exactly where they need to go, while cranes must travel along roads or paths, which can be difficult in remote areas.

Each roll of mesh weighs 4 metres and 300 kilograms daily; that is 224 metres of mesh weighing 16,800 kilograms.

The helicopter’s down draft also has the added benefit of dusting the rock face in preparation for meshing.

The meshing campaigns are conducted closely with our rope access teams, as more prominent rock faces require technicians who can scale heights.

Despite reworking our procedures from the ground up, the Campaign went as smoothly as possible. Factoring in the different methods and regulations for using helicopters at the site was a very specific challenge that our team at Koolan overcame.

The Campaign was carried out across all sections of the main pit, using rope access and areas worked on foot where no vehicles or cranes could access to place TECCO mesh.

The two main campaigns were carried out relatively quickly.

Overall, the campaign was carried out with 0 injuries or major incidents, another major feather in the cap of Vertech and our continued innovation journey.

The Vertech team would like to thank our clients, business partners, and employees for their continued support, and we look forward to working with them on future projects.

"*" indicates required fields