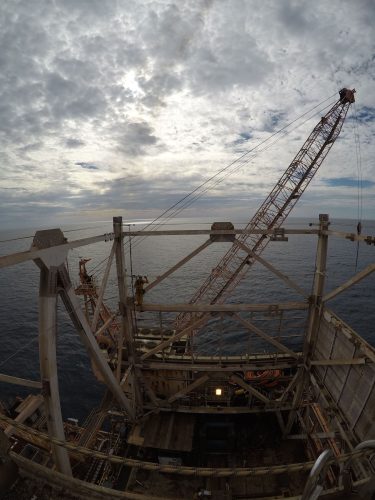

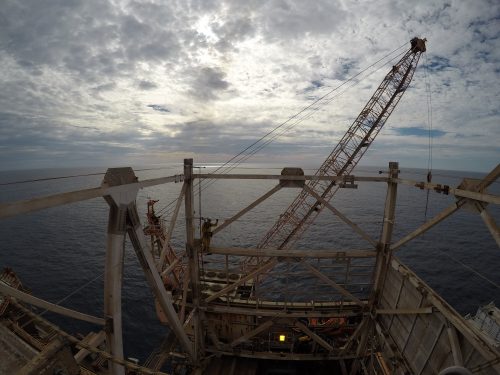

The Goodwyn Alpha, constructed in 1995, is an offshore production platform that produces dry gas and condensate. The structure weighs 55,000 tons and stands 290m tall. The facility is located 135km Northwest of Karratha and has a production capacity of 36,000 tons of gas and 11,000 tons of condensate.

GWA Derrick Decommissioning

Following changes to standards in the Gulf of Mexico after Hurricane Katrina, the remaining sections of the Goodwyn Alpha Derrick were decided to deconstruct and decommission.

Project Summary

Vertech’s involvement in the project began in the planning phase when it provided consultation services to Woodside’s EPCM as a technical authority on rope access heavy rigging methodologies.

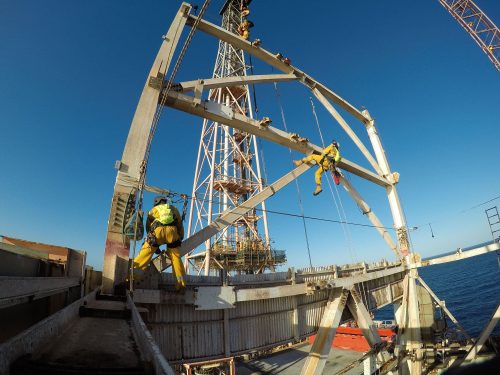

The project required specific safety measures to overcome the risks of working near an operational flare. Vertech is commonly contracted in Australasians to provide rope access services for high-risk and complex projects. During the execution of this project, Vertech removed 120 tonnes of steel without interruption to production.

Project Execution:

Vertech’s technicians on this project were essential to its success. Consistency of personnel and the ability to contribute to all areas of the scope were requirements. Multi-disciplined technicians ensured that POB (persons on board) numbers were kept to a minimum so that project activities did not affect the facility’s day-to-day operations.

Each member of the team was selected for their multiple competencies, including:

- Mechanical Trades

- Advanced Rigging

- Electrical Trades

- Rope Access Scaffolding

- Site Management

The scope employed a stick deconstruction methodology. Each lift was controlled using defined plans prepared pre-project by Vertech lifting specialists.

Isolated scaffold work platforms were constructed using rope access, avoiding the need for large scaffold access towers and approaches. The isolated work platforms were required so that heavy mechanical tooling could be used at various heights throughout the Derrick.

The discrete scaffold platforms reduced:

- Footprint of Materials Required Offshore

- Manual Handling Exposure

- Dropped Object Exposure

- Simultaneous Operations Activities